06.12.23 – Shelton Vision

AI-assisted quality control

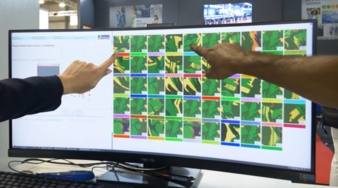

Having demonstrated its “WebSpector” automated fabric inspection system detecting faults on camouflage fabrics at speeds of up to 100 metres a minute during ITMA 2023, British Textile Machinery Association (BTMA) member Shelton Vision has secured a number of new orders in many fields of the textile industry.

Mark Shelton, Shelton Vision CEO and Managing Director, notes a significant industry shift towards imaging technology and automated fabric inspection due to challenges in recruiting and retaining manual inspection staff. The “WebSpector” system is said to surpass manual inspection, detecting over 98% of faults, aided by automatization and AI for real-time defect naming and grading accuracy. He said: “Not only this, using machine learning, the vision system automatically trains new styles, and our AI platform is continuously updating to achieve high accuracy of real time defect naming and grading to eliminate false positives and provide consistently accurate data for both roll cutting optimisation and yield increase, as well as for optimising fabric utilisation in panel cutting processes.”

Patterned fabric inspection

Building on its market leading vision system for plain, single colour textiles, Shelton´s patent-pending image processing techniques recognise and adapt to complex patterns – even those on fabric with significant distortion and deformation. Fabrics are not rigid and can be sheared or stretched while also being subject to local distortion, but the “WebSpector” system successfully deals with such anomalies in real time to provide a reliable inspection process at the same levels of plain fabric. The unique and advanced software techniques ensure a clean image, allowing the full detection of faults on fabrics running at high speeds. Validation through factory trials and installations has boosted interest, prompting Shelton to create a high-speed demonstration system for potential customers.

Spreading the word

The technology finds applications beyond automotive and one-piece woven airbag sectors, with increased adoption in performance wear, fashion, upholstery, and even carbon fiber composites manufacturing. Brands are actively advocating Shelton´s system to fabric suppliers, reinforcing the shift towards automated quality control in textile manufacturing. The British Textile Machinery Association´s CEO, Jason Kent, anticipates Shelton´s technology becoming the preferred solution in fault-free fabric manufacturing. “Shelton and the BTMA did some market research recently and early results show that even in lower labour cost markets there is now a strong appetite for investing in machine vision to automate the last major part of fabric manufacturing – quality control,” he added. Founded in 1940, the BTMA promotes British textile machinery globally, fostering collaboration between manufacturers and the textile industry.