26.03.24 – Uster Technologies

From manual to automated fabric inspection

Uster Technologies offers a flexible solution to upgrade fabric inspection from manual to automated. A step that offers mills higher profitability based on increased efficiency and quality. Integration in existing production lines is quick and easy, and the data flow also brings extra benefits.

The path to automation

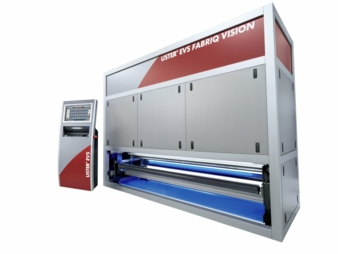

For maximum benefits – up to 50% lead time savings and 80% less waste – automated fabric inspection combines Uster “EVS Fabriq Vision” with Uster “Fabriq Assistant”. This integrates a reliable and sophisticated inspection system, delivering vital data, with practical analysis of that data to deliver the best results for users.Prerequisites for automatic fabric inspection begin with a detailed evaluation of the current process, to identify the critical steps. Typical questions users will be asked include “What kind of optimization do you expect and what changes would you like to make to the production process?” or “How does your final process step look before you ship the fabric to your customer?” At the end of this analysis, the steps towards integration are planned, including the choice of the right hardware and software needed to achieve automation in the fabric inspection process. The Uster “Fabriq Vision” inspection solution can be integrated into existing production lines – or used as an off-line inspection system. In both cases, the preconditions for optimal results from the optical system are the same: smooth and tension-controlled fabric flow, no creases in the fabric, stable light conditions in the inspection area and no dust or lint on the fabric. The inspection cameras feature state-of-the-art technology, positioned at various detection angles. Illumination makes defects visible and raises detection performance to the maximum. Uster “EVS Fabriq Vision” provides real-time alerts for operatives, showing all defects and automatically creating roll inspection charts. All detected faults are collected in a dataset and transferred to Uster “Fabriq Assistant”.

Introducing additional benefits to fabric production processes

Data generated by Uster fabric inspection systems feeds to Uster “Fabriq Assistant”, which creates statistics for quality and process improvement. Its automated features make Uster “Fabriq Assistant” more efficient and productive, as a reliable and tailored solution for processing, analyzing, and visualizing quality data. Connecting data is no longer a big deal. The Uster solution offers an open interface to transfer data to the ERP system and to the Optimized Cut Control (OCC), allowing maximized yield. Uster recommends a customer workshop to discuss data requirements, key parameters, data flow in production and how to create a powerful infrastructure. OCC allows an increased fabric yield after inspection. It is a software tool using the defect map from inspection, enabling automated cut optimization to be installed on any existing debatching or cutting line. It automatically identifies the correct cutting position for maximum fabric yield according to the customer’s quality requirements, and makes the cutting process highly efficient. Invisible synchronization marks (applied during inspection) indicate the position of defects and cut positions in a roll, so these are always under control, allowing the cutting table to run at maximum possible speed. When color consistency is critical, Uster “EVS Fabriq Shade” supports fabric producers to deliver a constant shade in end-products. The system provides standard shade measurements with high accuracy and continuously qualifies shade variation, based on a set reference point. To ensure lots have optimal color uniformity, the system offers grouping according to shade, for best fabric yield. Combining Uster “EVS Fabriq Shade” and Uster “EVS Fabriq Vision” in one process provides all relevant quality data in a single operation and increases the efficiency of fabric inspection. Automated fabric inspection requires newly-configured logistics as part of the detailed set-up plan – including a clear and traceable data flow for a paperless production. Finally, the calculation of the ROI will assure customers that profitability – as well as efficiency and quality – will also increase.

Ingo Kiefer, Senior Textile Technologist for fabric inspection at Uster Technologies, takes participants through the transition from manual to automated fabric inspection at the upcoming webinar.