04/08/2025 – SupplyX Barometer — auf Deutsch lesen

Supply chain digitalisation remains a major challenge

While digitization within Supply Chain Management (SCM) has been widely acknowledged from a strategic point of view, it has not yet been fully implemented in practice. This is shown by the results of the 22nd SupplyX Barometer.

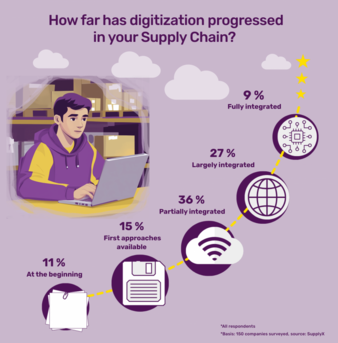

For the 22nd SupplyX Barometer 150 logistics managers were surveyed on the topic of “Digital change in Supply Chain Management”. When surveyed, 82% of companies stated that digitization is a must. However, a look at the actual implementation status reveals that only 9% of companies do have a fully digitally integrated supply chain to date. The majority claims being in a transition phase. Despite clear objectives, a significant number of organizations are struggling with structural or technical barriers.

For many companies, the most severe challenges when it comes to implementing digital strategies lie in the practical sphere: high implementation costs are perceived as a major burden by 39% of respondents. Data protection requirements and cybersecurity as well as the lack of interoperability of existing IT landscapes were also cited as major hurdles. A lack of uniform standards often means that applications and platforms exist side by side in isolation, which can lead to significant efficiency losses.

“Many companies know where they need to go. And yet, getting there is technically complex and organizationally challenging,” says Jörn von der Fecht, Chief Digital Officer at SupplyX, commenting on the results of the study. “The lack of standardized interfaces in particular often prevents systems from communicating with each other. This in turn leads to media disruptions, a lack of transparency and operational delays.”

High benefits are witnessed – especially in warehousing and planning

Where digital technologies are already being used consistently, there is clear added value. In warehouse and inventory management in particular, 61% of experts surveyed reported significant efficiency gains. In companies with 250 to 1,000 employees, this figure is even higher at 75%. Many organizations also benefit from data-based applications in forecasting and demand planning. Almost one in two respondents (48%) stated that this provides great added value in terms of planning reliability and resource utilization. At 67%, the figure is even higher in SMEs. Transport and route optimization also delivers measurable efficiency gains. 38% report high added value in this context.

The results clearly show: The added value of digitization is particularly visible in operational application areas. Intelligent technologies unfold their full potential where processes can be controlled in a data-driven manner. Accordingly, many companies are focusing their digitization plans precisely on this operational lever – especially where tangible efficiency gains have already become apparent.

Willingness to invest is present – but not across the board

Almost every other company (48%) is planning to invest in automated inventory management. This figure increases with the size of the company and shows that the greater the organizational complexity in companies, the more urgent the need to manage inventories digitally and identify bottlenecks at an early stage apparently becomes. 43% of respondents also want to use digital platforms to integrate their partners, while one in three companies (33%) seek to invest in data analysis and artificial intelligence.

At the same time, however, one in four respondents (27%) stated that they currently have no specific digitization measures planned. For Jörn von der Fecht, this is an alarming signal: “Those who do not invest in digital infrastructure now will find it difficult to remain competitive. In logistics in particular, the requirements for transparency, speed and resilience are constantly increasing. This certainly cannot be achieved with analog processes.”

Real-time data and networking as the next stage

Real-time data is also playing an increasingly important role. Almost every other company surveyed (48%) considers the use of real-time systems to be essential for agile supply chain management. For companies with up to 1,000 employees, this figure is as high as 92% – a strong sign of their high practical orientation and the need to react flexibly to volatile market changes. Nevertheless, only 41% of logistics managers state that they are already digitally networked with their customers and partners.

“The full potential of digital supply chains lies in end-to-end networking – both internally and externally. It’s only when information flows across company boundaries in real time that the speed of response that is needed in today’s volatile markets can be achieved,” says von der Fecht. “The digitization of SCM is no longer a topic for the future, it is strategically recognized and has been initiated in many cases. But it takes more than technology to turn digital strategies into measurable results: it takes courage to change, resources for implementation and reliable partners.”

The complete 22nd SupplyX Barometer is available for download free of charge.

About the Survey

Participants: 150 logistics managers

Method: Telephone interviews

Survey period: May 2025