03/09/2015 — auf Deutsch lesen

Hollanders: High quality Disperse printing

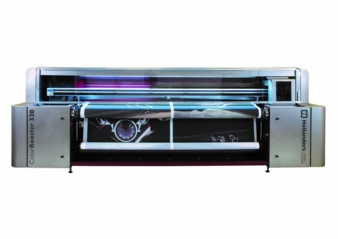

1 year after the introduction of the successful ColorBooster 250 Hollanders sold at FESPA 2015 in Cologne the first of its newest printer, the super wide ColorBooster 320, right the first day.

Looking at customer’s requirements Hollanders has seen a growing market demand for a flexible printer set-up that enables customers, also afterwards, to combine various configurations to meet their production needs and budget at that moment.

Jacco Aartsen Tuijn CEO of Hollanders said: “We see that customers require a flexible set-up of their printers and based on this principle the introduction of the ColorBooster 250 last year was absolute the right move and has given our sales an enormous boost the past year.”

“So it was the logical next step to extend this principle to a new big brother the ColorBooster 320” he continues “The flexibility in the head configuration has even improved giving the utmost flexibility in speed and number of colors”. “All our experiences of the last year with our CB250 are put into this development”. ”One example: customers can change their own heads if necessary and waiting time for a service engineer belongs to the past in this case”. “Besides with the typical feature of unattended printing and overnight printing we think that we have built not only the most reliable and flexible but also a printer with the highest efficiency and lowest m2 price”.

CTO Peter Hollanders completes: “Also for us it was a surprise that we sold the new 320 printer directly the first day and in combination with the 320 ColorFix” “We have had our expectations for the new 320 based on the 250 printer sales, but you can only dream of such a sale at the most competitive market place that Fespa surely is”.

With a base price starting at € 99,000.- for the CB250 and € 131,5000.- for the super wide CB320, both printers are very competitive.

Advantages of the ColorBooster 250 and 320 are: • Ricoh Gen5 heads • Customer changeable heads with an own developed error free mounting system • Unique build-in head shower and auto-cleaning function • Open ink system • Hollanders High and Low energy disperse dye selection • Wide color gamut and the highest UV resistance • In-line drying • Anti-ink-mist system • Optional internal printer temperature and humidity control makes workspace control redundant • Low overall energy consumption • Small operating space • High functionality and productivity at the best m2 price.

Cleaning is easy because the exhaust hood can be opened, allowing access to the complete printer

The ColorBooster 250 and 320 are the newest printers in a range including the unique Double Sided ColorBooster DS.

About Hollanders Printing Sytems

Based in the Netherlands Hollanders Printing Sytems B.V., which was founded in 2003 by Peter Hollanders, develops and manufactures digital textile printers and machinery for disperse fixation and washing that have been designed to achieve the highest possible uptime, combined with the lowest possible purchase and operational costs.Hollanders is focussing towards the digital disperse textile printing processes, with textile machinery dedicated to the markets of soft signage and home interior. Continuous innovation has led to a range of finishing equipment and modular single and double sided printers with the highest possible performance, reproducibility and reliability as typical features. The modularity of the newest printer series enables customers, also afterwards, to combine various configurations to their production needs and budget at that moment.