20/02/2026 – VDMA joint stand, Hall 12/C56 — auf Deutsch lesen

Barmag at Techtextil 2026

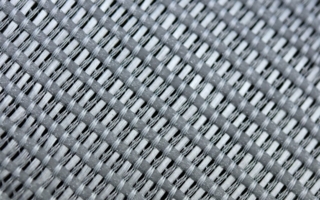

Barmag will present technologies for producing industrial filament yarns used in airbags, seat belts and other technical applications, focusing on stable processes and consistently high yarn quality.

Solutions for safety-critical automotive applications

Modern vehicles contain an average of 30 to 35 kilograms of technical yarns. Airbags mainly rely on polyamide yarns, with polyester steadily gaining importance. Barmag's systems are designed for energy-efficient production and reproducible results. Their process stability supports consistent yarn properties under varying climatic and operational conditions, as highlighted in the company's technology statement.

Precision in high-tenacity yarn processing

A single seat belt consists of around 300 high-tenacity filaments, each able to withstand forces exceeding three tonnes before yielding in a controlled manner. The patented Single Filament Layer technology guides each filament individually to protect it from mechanical stress. This controlled handling contributes to uniform processing conditions, which is essential for achieving reliable tensile characteristics.

High-performance yarns and spunbond applications

Barmag also highlights solutions for yarns used in geotextiles, road construction and further industrial fields. The equipment can efficiently produce three 6000-denier yarns that can be combined into higher titers in a cost-effective process. Complementing this, the Neumag product brand provides spunbond technologies for polyester and polypropylene geotextiles with high throughput and strong process stability.

Relevance for technical textile manufacturers

For manufacturers of technical textiles, the presentation offers a reference point for assessing process consistency and material performance across different applications. The showcased systems address key requirements of the sector, from defined tensile behaviour to reliable yarn stability during demanding production steps.