04/05/2021 – Series: Realistic simulation of technical textiles – Part 3 — auf Deutsch lesen

Fraunhofer ITWM: FIFST for complex load scenarios

Simulation methods for efficient prediction of textile behavior under stretching, shear, bending, torsion, or compression. by Annika Dreßler

Thanks to the “TexMath” software program, it is possible to simulate mechanical material properties and optimize textile products. Techniques like these are particularly in demand in the sports, medical and clothing industries. The TexMath software developed by the Fraunhofer Institute for Industrial Mathematics ITWM consists of three components (link to part 1, link to part 2). Now we will present the tool “FIFST”.

With TexMath, the “Technical Textiles” team of the “Flow and Material Simulation” department at Fraunhofer ITWM has taken up the challenge of developing simulation methods that allow efficient prediction of textile behavior under stretch, shear, bending, torsion, or compression. The software also allows simulation of some special kinds of wrinkling under stretch, shrinkage of yarns or critical shear angles throughout the manufacturing process.

Deformation and stress

The FIFST component is used for complex stress scenarios: “The tool can simulate stretching and draping as well as the textile production process,” says project member Dr. David Neusius. This includes, for example, the process of knitting, the pulling of the textile from the knitting machine, as well as the stress on the textile during the tightening process. Thanks to the simulation, the design of the knitted fabric can be adapted to specified requirement profiles. In addition, FIFST makes individualized machine control possible, allowing personalized textiles or product-specific designs to be implemented.

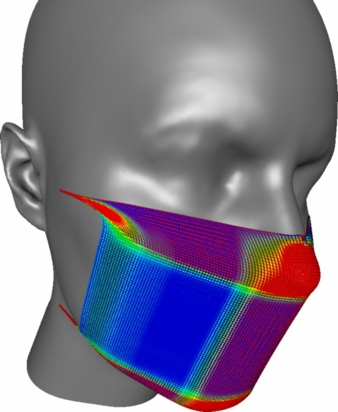

The tool thus enables the simulation of the movement and interaction of many yarns over millions of nodes, which is a unique selling point of FIFST. In addition, it is possible to draw textiles virtually over a surface triangulation given in STL format (put on). Thus, wrinkling can be studied and pore size of the tightened textiles can be minimized.

Useful connections

All of the tools mentioned have interfaces with each other as well as connections to the “GeoDict” software from the Fraunhofer spin-off Math2Market, which can be used, for example, to perform fluid mechanics simulations on the textiles.

This enables the targeted design of breathable or wind-/virus-proof textiles in an iterative process. Textiles can be tried on virtually and if there are pores that are too large or too small at certain points and the effective air or liquid permeability does not meet the requirements, the knitting machine parameters are adjusted or yarns are exchanged so that the fluid mechanical requirements for the textile product are met. In this way, many textile products can be designed and optimized virtually on the computer before the actual knitting and weaving process is starting.