03/09/2025 – Protective wear

Anti-static protective clothing in high demand

Growing demand for anti-static protective clothing is being driven by expansion of the electronics industry and growing awareness of workplace safety, according to “Anti-static technologies for performance apparel: opportunities in a fast growing market”, a 27-page report from the global business information company Textiles Intelligence.

Everyday electric shocks from static electricity are a common occurrence and generally pose little risk to the human body. However, static electricity is a critical issue in the electronics industry, where it can damage electronic devices. Also, a sudden discharge of static electricity can cause fires or explosions in some environments. In workplaces, people are the greatest source of static charge and therefore anti-static measures such as protective clothing are required in these environments. Significantly, workwear is the largest market for anti-static apparel, and the largest consumer within this market is the electronics and computer industry.

A rise in demand for personal protective equipment

The market for anti-static products – including fibres, yarns, fabrics and apparel, among others – is highly specialised. Some of the most notable providers of anti-static fabrics for use in the manufacture of protective clothing are Burlington Fabrics, Carrington Textiles, DuPont, K&K, Klopman International and TenCate Protective Fabrics. Notably, anti-static capabilities also feature in many flame resistant fabrics. Common conductive elements used in anti-static fabrics include carbon, copper, graphene, metallic salts, silver or stainless steel, and the choice of conductive product will depend partly on the end use and the required level of protection.

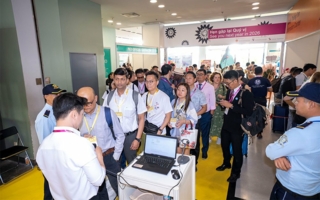

Looking ahead, the market for anti-static products is set to grow significantly for a number of reasons, including: the ever increasing expansion of electronics in consumer products; miniaturisation of electronic components, which are more susceptible to static charge; growing awareness of workplace safety; a rise in demand for personal protective equipment (PPE); and strong growth in certain end-use markets, including the automotive industry and packaging. Geographically, strong growth is forecast for Asia – and for China and India in particular – as a result of strong growth in manufacturing activity, low production costs and rapid expansion of the electronics industry in the region. With this in mind, there could be significant upheaval in the market for anti-static products as a result of the shift towards production in Asia, and a growing requirement among buyers for products with advanced anti-static properties which can provide protection for miniaturised electronic components.

For further information or to purchase this report, visit www.textilesintelligence.com.