16/10/2020 – Wicket 22: Fighting Corona with smart Chemistry — auf Deutsch lesen

CHT produces and sells a solution for the antiviral functionalization of textiles

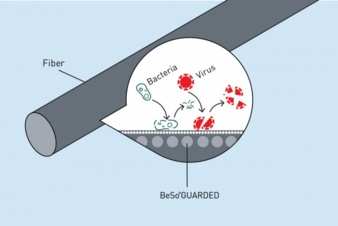

The textiles impregnated with the solution produced and distributed by CHT deactivate viruses that stick to the surface within minutes.

Thanks to a new impregnation solution, it is now possible to equip textiles with a highly effective protection against viruses and bacteria. This has been achieved by combining the well-established silver technology with vesicle technology. This combination deactivates the enveloped viruses within a few minutes, an effect that has also been verified in labs. © sutichak/stock.adobe.com

The chemical industry is indispensable in the fight against corona as it delivers important elements for manufacturing disinfectants and protective gear. Thanks to a new impregnation solution, it is now possible to equip textiles with a highly effective protection against viruses and bacteria. This has been achieved by combining the well-established silver technology with vesicle technology. This combination deactivates the enveloped viruses within a few minutes, an effect that has also been verified in labs.

From a shirt to the upholstery of a sofa to an airbag, textiles surround us everywhere. But it is the targeted use of chemicals that makes textiles easy to clean, heat resistant or water resistant – qualities that people take for granted these days. Textile chemicals, a subset of applied chemistry, is concerned not only with the production, extraction and processing of textile fibers. Other important focus areas are the refinement of textiles; the development and use of textile devices, textile pigments and textile care products, etc.; and textile testing.

Robert Zyschka, Head of Application Field Finishing at CHT Germany GmbH, knows all the technologies that can improve the functioning of textiles or can integrate new functions into a textile. And he’s particularly delighted that in the middle of the corona pandemic, CHT has for several months been producing and distributing a solution that gives textiles an antiviral and antibacterial protection. After all, says textile engineer Zyschka, pathogens “can also be transmitted and spread through textiles.” At room temperature, the coronavirus (SARS-CoV-2) remains active on textiles for up to two days, which makes it dangerous, according to the Journal of Hospital Infection (issue 104). Therefore, an important way to stop the spread of SARS-CoV-2 and other pathogenic viruses is to “produce textiles whose surface is capable of slowing the growth of bacteria and of deactivating viruses,” says Zyschka.

The solution manufactured by CHT was developed by the HeiQGroup, a Swiss company that, like CHT, offers solutions for manufacturing specialized textiles. In order to equip the textiles with the antiviral and antibacterial protection, the so-called HeiQ Viroblock NPJ03 is applied on textiles at the end of the manufacturing process by the textile producers or textile refiners themselves through wet-refinement processes. In principle, the antiviral and antibacterial coating can be used on all types of fibers and non-woven fabrics.

According to Zyschka, the protection can survive up to 10 to 30 washings, depending on the type of fiber and washing method. And the protection could even be refreshed afterwards – that, at least, is the vision of CHT, which is currently working on such a solution together with an industrial laundry for medical textiles. Therefore, the solution is suitable not only for disposable medical or cosmetic textiles, but also for a much broader number of uses.

Double protection

The antiviral and antibacterial performance of this solution is derived from two technologies. The well-known silver technology, which has been used for decades, fights both viruses and bacteria. Silver ions that have been applied to textiles react, among others, with sulfur groups, which are in many proteins of the bacteria cells and disrupt the metabolism and cell division of these cells.

But silver is also effective against viruses that, strictly speaking, are not living organisms but “merely” infectious substances. In order to “survive” and reproduce, the viruses must invade the host cells of plants, animals or people. This can trigger dangerous diseases in human beings, including the flu, chicken pox, HIV or Covid-19. Viruses with a lipid shell will be more successful in penetrating a host cell than non-enveloped viruses because the shell allows the viruses to penetrate the host’s immune defenses more easily and adapt themselves better. This is an evolutionary advantage that explains why all new pathogenic viruses, such as SARS-CoV-2 or the Ebola virus, are enveloped.

Like a magnet, the positively loaded silver ions attract the viral particles that are loaded in the opposite direction and bind them permanently through the creation of silver sulfide. As a result, the virus is not just immobilized; due to the binding with the sulfur groups, the virus is at the same time deactivated. That said, this process does not happen fast, so chains of infection can only be broken to a limited degree. However, by combining silver technology with vesicle technology, “a true jump in speed is achieved in deactivating the viruses,” says Zyschka.

Vesicles destabilize virus shell

In order to destroy the enveloped viruses within a few minutes, so-called vesicles come into play. Vesicles are artificially produced, small bubble-like structures. (They are also often called liposomes.) Vesicles are used, among others, in cosmetics in order to channel substances into a cell. The vesicles used for the protection solution consist of a lipid double layer that, unlike the enveloped viruses, does not contain any cholesterol. As a consequence, a concentration gradient is created with regard to the cholesterol content that strives for an immediate balance – as always in nature. This means that an increased number of cholesterol molecules leave the virus membrane and become diffused into the vesicles, causing the shell of the viruses to lose its structure- and strength-based building blocks. The shell becomes brittle and eventually collapses, and the virus can no longer infect new host cells.

- Textiles treated with this antiviral and antibacterial protection will deactivate viruses that stick to the surface within minutes, provided the products that are manufactured with the protection are used in the correct way.

- A recent test report according to ISO 18184 certifies a 99.99% antiviral effectiveness for a non-woven fabric treated with this innovation.

High level of protection – and safe

In order to reduce rates of transmission and infection in a lasting manner, medical textiles like gowns or caps should definitely be impregnated with this protection, argues Zyschka. After all, due to shortages during pandemics, protective clothing is often worn longer than it should be worn. Therefore, halting the spread of viruses through clothing is vital – and possible too.

But “in order to thoroughly protect people from the virus and keep economies healthy,” everyday clothing or seat coverings in buses, trains or airplanes should also be treated with the product, continues textile engineer Zyschka. He has no concerns about any health or environmental risks. “I know of no study that has ever made a problem out of the silver ions that have already been used since decades, or of the vesicles that can be found in cosmetics. The functionalization of textiles with this innovation is therefore a safe and efficient way to break possible chains of infection.”

Syra Thiel