11/11/2022 – Adhesive systems for technical textiles — auf Deutsch lesen

Sustainable laminating with (bio) hot melt adhesives

There is a variety of adhesive systems for the lamination of technical textiles and foils. In the sector of hot melt adhesives, biopolymers can help to implement more sustainable laminating solutions and material combinations.

Classic, non-reactive hot melt adhesives already offer a number of environmentally relevant advantages compared to other adhesive systems. They are considered to be safe, low-emission, solvent- and plasticizer-free adhesives and are not labeled as hazardous materials. So far, however, mainly petroleum-based raw materials have been used for production.

Alternatives to fossil based raw materials

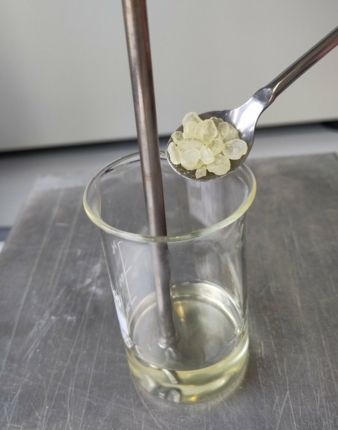

Possible alternatives are polymers whose base monomers are obtained from vegetable raw materials such as corn or sugar cane. From a technical point of view PLA (polylactic acid) and PBS (polybutylene succinate) are currently the most interesting materials. They belong to the group of polyesters and have properties similar to comparable conventional products, and when formulated as a hot melt adhesive, they offer a comparatively broad spectrum of adhesion to a wide variety of materials. PLA and PBS are also considered biodegradable, corresponding certificates are available.

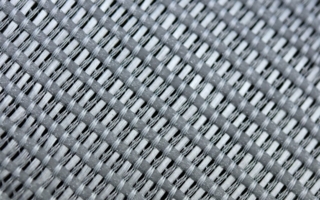

Non-woven fabrics and technical films can also be made from PLA and PBS, which, in combination with PLA or PBS-based hotmelts, can be used to laminate monomaterial, which can be used in various areas of application and offer ideal conditions for recycling after the use phase. Possible applications are, for example, packaging, hygiene products or carpets.

Development of sustainable hot-melt adhesives

In its own laboratory, together with partners, Wico develops PLA- and PBS-based hot-melt adhesives, which can be formulated application-specifically for different industries and customers, with the aim of making existing processes more sustainable and opening up new areas of application.

Several processes are available at Wico for lamination or pre-coating. These include flat-bed lamination, in which PLA or PBS adhesive webs and films are used, and the powder scattering process, in which the hotmelt powder is scattered onto the substrate to be coated. In both methods, the adhesive is then fixed using heat and pressure. Furthermore, the roller coating process offers the possibility of applying the hot melt directly from the melt in liquid form. Different coating geometries can be realized by using different application rollers.

Wico is open to further cooperation with interested partners in order to advance these new products in terms of performance and commercial use.