03/12/2019 – Dynamic Energy Supply (DEV) protects yarns in case of power failure

Michael Koch help spinning machines

The textile industry is primarily active in countries where the electrical power supply is not always reliable and guaranteed everywhere.

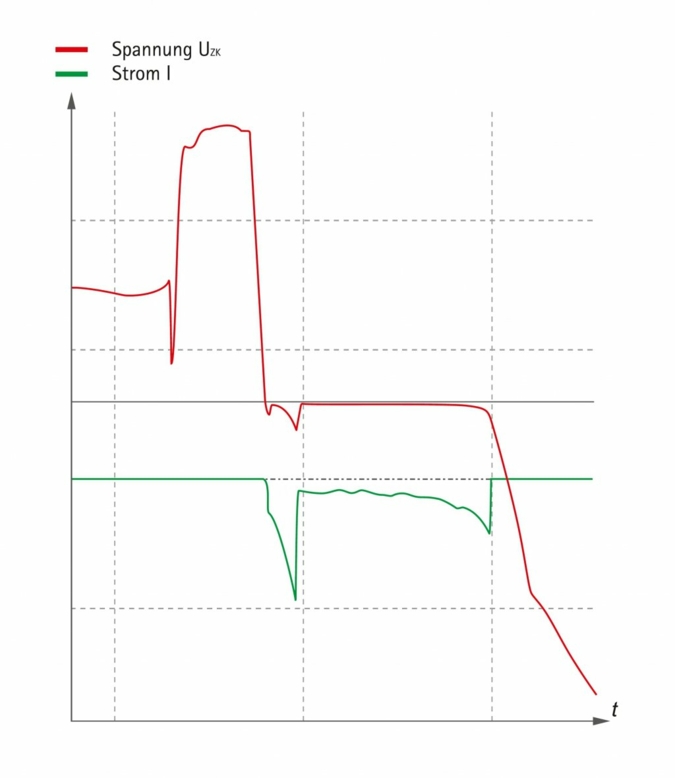

Problem and solution at a glance. Kinetic energy increases the DC link voltage which then drops. The DEV Dynamic Energy Supply from Koch keeps the voltage stable at a predefined level until its energy is consumed. The current course (green) shows the use of an imaginary zero line from the negative: the requirement is met until full stop (peak), then rises slightly because of the dwindling amount of energy. © Michael Koch GmbH

End product of the roving frame: the so-called rovings wound up on spools. Thanks to the DEV Dynamic Energy Supply from Koch, the process runs without yarn breakage even with an unstable power supply. © Michael Koch GmbH

Dynamic Energy Supply DEV 2.0 from Michael Koch GmbH ensures the necessary energy for electric drives during voltage fluctuations or power failure. © Michael Koch GmbH

Problem and solution at a glance. Kinetic energy increases the DC link voltage which then drops. The DEV Dynamic Energy Supply from Koch keeps the voltage stable at a predefined level until its energy is consumed. The current course (green) shows the use of an imaginary zero line from the negative: the requirement is met until full stop (peak), then rises slightly because of the dwindling amount of energy. © Michael Koch GmbH