19/11/2025 – Innovative steam recycling

Cascade’s impact on textile production

Cascade by Karl Mayer enables Getzner Textil to achieve significant energy savings and sustainability goals. Learn more about this groundbreaking steam recycling system.

A step forward in sustainable textile production

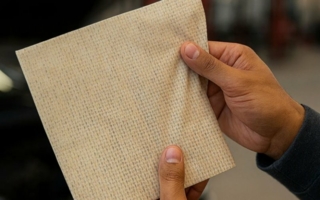

Getzner Textil AG, a company with over 200 years of history, has once again demonstrated its commitment to innovation and sustainability. Known for producing fabrics for African fashion, corporate wear, and technical textiles, Getzner installed Karl Mayer’s Prosize staple fibre sizing machine in 2024, equipped with the newly launched Cascade technology. This innovative system optimises energy use during the drying process, setting new benchmarks for efficiency and environmental responsibility.

Proven energy savings with Cascade

Cascade technology recycles process steam generated during drying in cylinder dryers, enabling efficient energy reuse within the machine. Tests conducted at Getzner Textil revealed a steam consumption reduction of up to 3.9%, with peaks reaching 7%. During full machine operation, 51 kg/h of the total 1,295 kg/h steam requirement was directly recovered through Cascade’s inline recycling system. Even at lower capacity utilisation, the system demonstrated measurable savings, influenced by process conditions such as temperature gradients between cylinder sections.

Economic and environmental benefits

The reduced consumption of live steam translates into tangible cost savings and a lower carbon footprint. Under typical operating conditions – 5,000 hours per year with an efficiency rate of 83% – Getzner Textil saves approximately €8,500 annually, while cutting CO2 emissions by 59 tons per year. Cascade also addresses common inefficiencies in boiler house operations, where excess thermal energy from condensate often goes to waste. By minimising these losses, Cascade provides a sustainable solution without requiring additional investments in machine peripherals.

Setting a precedent for the industry

Cascade technology exemplifies how innovative solutions can drive sustainability in the textile sector. Getzner Textil’s success highlights the potential for energy-efficient practices to deliver both environmental and economic benefits. As global demand for sustainable manufacturing grows, Cascade offers a model for other industry players to follow.