25/04/2025 – Technical yarns — auf Deutsch lesen

Innovative air interlacing jets for spinning

The new generation of high-performance air interlacing jets for spinning brings uniform interlacing density and heavy, reliable knots for high-tenacity yarn. Heberlein’s latest PolyJet-TG-3 achieves more than 12 knots per meter with “1100f98dtex” and “1670f98dtex”.

Thanks to the new quality of the yarn, tensile strength, elongation, and elasticity show a smaller variation, leading to improved unwinding behaviour of bobbins, resulting in higher production efficiency. Producers of demanding technical yarns can achieve yarns with unmatched even and uniform interlacing density with the PolyJet-TG-3 (TopAir) as illustrated in the second picture comparing the magnifications (factor x1.25) of two PES dtex1100f192 yarns.

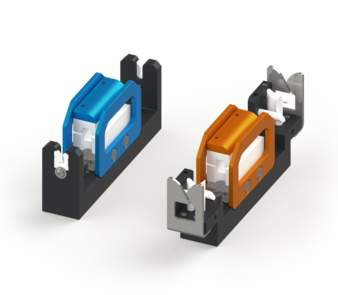

Typical Heberlein extra benefits: PolyJet-TG-3 and other high-performance air interlacing jets for textile and technical yarns offer a unique quick-release system, so jet packs can be exchanged within seconds, with just a single 180-degree turn. And the lateral threading slot ensures maximum operational reliability. The jets are also characterised by a compact, space-saving design and include a roll bar to protect the ceramic surfaces.

Heberlein Technology is a leading provider of air interlacing and air texturing jets for synthetic continuous filament yarns. With expertise since 1835, they develop and manufacture high-end solutions with valuable extras in Switzerland.