27/04/2021 – Sustainability – Circular Economy — auf Deutsch lesen

CHT: The first fabric softener based on recycled silicone

With Tubingal Rise the CHT Group is supporting the SDGs of the UN and underlining its own commitment to sustainability. by Annabel Edel, CHT Group

The transformation from a linear economy to a circular economy is a vital process that requires cross-industry collaboration. Tubingal Rise is the first fabric softener based on recycled silicone. Following the circular economy model, end-of-life silicone products are recycled and converted into a new softener. By doing this, the CHT Group is supporting the SDGs (Sustainable Development Goals) of the United Nations and underlining its own commitment to sustainability.

- Trend researchers have declared “neo-ecology” the most important megatrend of the 2020s. It describes the transformation to a resource-efficient, sustainable economy that is taking place in society.

- As a forward-looking strategy for improved resource efficiency, a circular economy is an important aspect of this development and is becoming increasingly important particularly for millennial consumers. Product characteristics that bring together added value and longevity are decisive factors that influence purchase decisions.

- In particular, the new generation values the sustainable ideals of swapping and reusing, especially when it comes to preserving the value of an item of clothing for longer. As a result, textile products not only need to fulfill fashion aspects and functionality expections, but also combine characteristics like longevity and resource protection.

- On the back of this trend, recycled fibers are increasingly gaining importance. More and more brands are making a commitment to increasing the share of recycled materials in their collections.

- Sportswear manufacturer Adidas already uses more than 50 percent recycled polyester in the manufacture of its products. Clothing retail company H&M is also planning to switch entirely to recycled or sustainable materials by 2030.

However, the circular economy approach should not be restricted to just the recycling of fibers themselves, but should also be extended to finishing auxiliaries. The share of recycled and renewable raw materials in textile auxiliaries should be continuously increased. And it is precisely here that CHT comes in – with the development of a sustainable and eco-friendly softener.

Circular economy and Sustainable Development Goals (SDGs)

The principle behind a circular economy is that products are reused for as long as possible or recycled. This extends the lifecycle of products, leads to a significant reduction in waste and ensures that the full value of the resource can be exploited. The outcome: sustainable production and a reduction in negative climate consequences.

The circular economy as well as climate protection are also part of the global targets for sustainable development that have been set out by the United Nations in the so-called Sustainable Development Goals (SDGs). Goal 12 – responsible consumption and production – sets out demands for more environmentally compatible handling of chemicals and waste as well as a significant reduction of waste volumes through reuse and recycling. Goal 13 – taking urgent action to combat climate change and its impacts – issues a challenge to politics and industry to incorporate appropriate climate protection measures in their strategies.

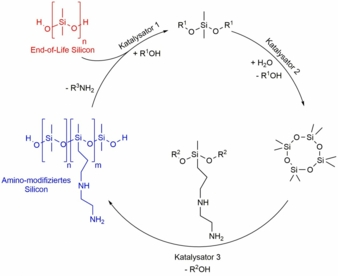

Recycling of end-of-life silicone products

Silicone is a versatile material that finds use in a wide range of different applications, and as such its commercial importance is significant. Global sales in the silicone market in 2017 amounted to over USD 16.3 billion. Silicones are an integral part of textile finishing as softeners, waterproofing agents, defoaming agents or lubricants.

- However, the production of silicones is extremely energy intensive. In order to fully exploit the value of this resource, end-of-life silicone products are recycled. As a result, today’s silicone waste can be used to produce an important alternative raw material for tomorrow.

- This approach to silicone recycling follows the waste-tovalue process and takes place across several stages. The end- of-life polymers are catalytically split into silicone monomers, are modified, and then finally polymerized into e.g. a new amino-modified silicone in virgin quality, which can be formulated into a fabric softener.

First fabric softener made of recycled silicone

In the past, production methods for manufacturing silicone fabric softeners were based entirely on linear concepts. With the development and production of Tubingal Rise (Recycled Innovative Silicone Emulsion), the world’s first fabric softener made of more than 60 percent recycled and reprocessed silicone waste and renewable bio-based emulsifiers has now been made available to the market. The quality of this product deserves to be mentioned, as it is identical to a silicone softener made of primary raw materials.

- The softener consisting of recycled silicone is suitable for all types of fiber.

- Potential areas of application include apparel, sports, and outdoor clothing, as well as home textiles.

- Tubingal Rise is the perfect match to recycled materials in order to achieve a fully integrated recycling concept.

Tubingal Rise also meets the wide-ranging requirements for textile standards (Bluesign, ZDHC, GOTS, Standard 100 by Oeko-Tex, and GRS). One important characteristic of this recycled softener is that it has been specially designed to be suitable for the production of textile products that are certified to the GRS Standard (Global Recycled Standard).

In addition, the innovative CHT effects “BeSoSoft” and “BeSoActive” can also be achieved with application of Tubingal Rise.

Tubingal Rise

The hydrophilic softener is a microemulsion with a mean particle size of <100 nm. This means the active ingredients can penetrate far into the interior of the fiber, making it possible to achieve exceptional core softness with a very soft, flowing feel.

Characteristic properties of Tubingal Rise:

- made of recycled silicone and renewable bio-based emulsifiers

- hydrophilic silicone softener, microemulsion

- soft, flowing feel with pronounced core softness

- treated products have very good re-wetting properties

- improved sewability

- improved tear resistance

- combinable with selected optical brighteners

- suitable for white fabrics

- suitable for pad and spray application

Not only can Tubingal Rise be used to achieve excellent softness (BeSoSoft), but the innovative product also serves as an processing aid by noticeably improving the confection of clothing products and their properties while being used/worn.

Sewability, tear strength, wicking height

Embrittlement and losses in strength, as well as the everincreasing speeds at which industrial sewing machines run, can cause damage in the form of sewing damages, which impairs the sewability of the textiles. This can be avoided by applying Tubingal Rise, which delivers excellent surface smoothness. The flexibility of meshes is strengthened, and friction between the sewing needle and the textiles (fiber/metal friction) is reduced significantly – by up to 75 percent. This avoids unnecessary textile wastage.

Tear strength is an indicator for the wear of woven fabrics during subsequent use. Tubingal Rise compensates not only the embrittlement of the fabric, but also strength losses, which was significantly improved by up to 75 percent on recycled cotton fabric. This means the durability of clothes during wearing is greatly improved.

In general, untreated textiles made of synthetic fibers offer only limited wear comfort, as they can absorb almost no moisture. The same applies to recycled synthetic fibers.

In order to achieve good moisture absorption, textiles are functionalized with a suitable finishing agent, thus upgrading the performance. In this way, hydrophobic properties are transformed into hydrophilic properties. With Tubingal Rise, good moisture transport and fastdrying properties are ensured (BeSoActive). Both are core properties for the moisture management of modern functional textiles. Hydrophilic textiles show a better moisture absorption; moistures are absorbed easily and transported to the outside, where they can evaporate. The determination of the wicking properties is a rate for the hydrophilic properties of textiles. The wicking height with Tubingal Rise is up to 85 percent higher than in untreated products.

Outlook

The transformation from a linear economy to a circular economy is unstoppable. The new generation of consumers demands sustainable products that are manufactured in a way that protects resources. The entire textile industry has recognized this demand and is increasingly focusing on recycled materials and renewable bio-based raw materials – as demanded in the UN’s Sustainable Development Goals (SDGs). Globally active international corporations are playing a leading role in the process.

To date, the circular economy strategy has been applied primarily to recycled fibers. But in the future we can expect to see this trend also make its way into the world of textile finishing to an increasing degree. CHT has already set out on a clear path down this road. Whereas the previous production of textile auxiliaries for textile functionalization was based on the use of primary raw materials, a softener made from recycled silicone and renewable bio-based emulsifiers is now available for the first time for this market. Tubingal Rise enriches recycled materials by creating a fully integrated and resource-efficient recycling-based product true to the principles of a modern circular economy.