26/01/2024 – Whole garment knitting

Shima Seiki to exhibit at DTG 2024

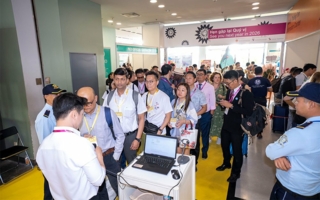

Computerized flat knitting solutions provider Shima Seiki Mfg., Ltd. of Wakayama, Japan is exhibiting at the 18th Dhaka International Textile & Garment Machinery Exhibition (DTG 2024) in Dhaka, Bangladesh, in cooperation with its partner Pacific Associates Ltd. Operating in Bangladesh since 1996, this is the 14th time the Japanese manufacturer is participating in DTG.

As the Bangladeshi textile industry calls for sustainable production through innovation and digitalization, the market is keen to establish effective business models that support such production.

Showcasing whole garment knitting machinery

For the first time in its DTG history, Shima Seiki´s lineup consists entirely of whole garment knitting machines, being capable of knitting an entire garment in one piece without the need for linking or sewing, while using only the material required to knit one garment at a time, aligns also with the industry´s push towards sustainable production through digitalization.

The highlight of the exhibition includes the “MACH2 XS153” whole garment knitting machine in 15L gauge, capable of producing high-quality fine gauge whole garment knitwear without the need for linking or sewing. Additionally, the “SWG091N2 Mini” whole garment knitting machine in 15 gauge is said to offer compact and economical solutions for whole garment production across various items. A unique aspect is the “N.SVR183” machine, part of Shima Sheiki´s global standard in shaped knitting. This model allows for whole garment knitwear production using every other needle in fine gauge, providing flexibility and entry-level options for sustainable production.

Offering digital solutions

Accompanying these machines is the demonstration of the “SDS-One Apex4” design system, a core element of the “Total Fashion System” concept. This system offers comprehensive support throughout the supply chain, integrating production into a seamless workflow from yarn development to sales promotion. It improves the product planningand design evaluation process by replacing physical samples with digital prototypes. Based on photo-realistic simulations, these virtual samples are said to minimize the need for actual sample-making, realizing significant savings in time, cost and material.

As a result, when combined with whole garment knitting machines, this approach establishes a sustainable planning and production foundation, emphasizing commitment to innovation and environmental responsibility.