08.12.21 – Clothing as an “environmental chamber”

Looking back ahead: In dialog with David J. Gerber

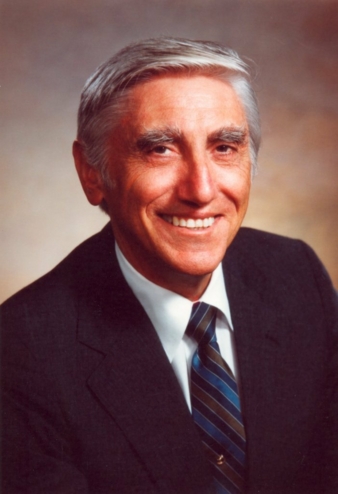

textile network succeeded in winning David J. Gerber, the son of the inventor and remarkable entrepreneur Joe Gerber, for an extended dialog – part 1.

In the course of our interview series with outstanding personalities on critical topics in view of today’s challenges in the apparel industry, textile network succeeded in winning David J. Gerber, the son of the inventor and remarkable entrepreneur Joe Gerber, founder of Gerber Scientific and Gerber (Garment) Technology for an extended dialog: The focus of the conversation, conducted by our correspondent, Yvonne Heinen-Foudeh, is the upcoming transformation processes along market needs.

textile network: “Apparel represents one of the largest consumer goods sectors in the world. And one with a far too large carbon footprint. Each year millions of tons of clothes are produced, which will be worn or (too often) simply discarded and then (too often) burned. The global fashion business is also considered to be a major contributor of the plastic microfibers entering our oceans. The call from all kind of social groups, governments, and NGOs for the fashion industry to reinvent itself is growing and requires infrastructure and the technologies to implement recycling. If Joe Gerber were still alive, would he also have been concerned by the essential challenge of massive overproduction for apparel? And which approach may he have chosen to tackle this major problem of the industry. In light of the given complexity how would he have prioritized?”

David J. Gerber: My father was motivated by considerations for the social good, but this is a double-edged sword in the context of your question. In creating automation systems, my father facilitated the growth of the apparel industry through productivity and quality. This improved living standards through lower prices and higher quantity of demand for apparel to be produced.

That said, my father was sensitive to environmental concerns and he recognized that automation in the apparel industry could mitigate environmental impacts. His concept of automated cutting improved material utilization by allowing pattern pieces to be nested tightly. The broader manufacturing automation systems pioneered by Gerber Technology facilitated inventory management and just-in-time processes, reducing inventory waste and end-of-season returns. These systems also reduced defects and improved quality, fit, customization, and choice, thereby improving acceptance of clothing. My father would have continued to improve and extend these capabilities.

textile network: As you elaborate your father was motivated by considerations for the social good and was sensitive to environmental concerns. Besides commercial factors, what social and environmental demands would drive him today to prioritize inventive efforts?

David J. Gerber: First, I should point out that he believed in social benefits of automation. For my father, who came to America as a refugee from Austria during the second world war, standard of living meant political and social as well as economic stability. Although he was aware of job loss concerns from automation, he felt technological innovation would continue to be a source of growth. He also felt that computers could promote human creativity, improve labor conditions, allow humankind to explore the universe, and treat the sick, all of which were important to him. He was also patriotic toward the country that took him in and gave him opportunity, and he saw technology as the key to retaining the U.S. apparel industry.

I can’t predict how he would address today’s environmental and social challenges in the apparel industry. With my father, this could be anything – a recycling method, new industrial uses for waste cloth, a friendly way to break down the fibers, a new material for efficiently making clothing. He might start with numerous projects to find a process so economical that clothing from such material becomes an attractive substitute (for some applications). In view of the urgency of circular models, he would have not only recommended but also become personally engaged in facilitating close cooperation between the textile and apparel industry and those responsible for creating the necessary infrastructures. He would also look for ways to enable high-value clothing based on added functionality. He thought of clothing as the person’s ‘environmental chamber’ that could be regulated, customized, and augmented with what's now called ‘wearable electronics’.

The questions on behalf of textile network were asked by Yvonne Heinen-Foudeh.

Continue reading the second part of the dialog on our website on December 22, 2021.

- The name Gerber will always be associated with fundamental technological progress in the textile and apparel industry, among other industries. It was Heinz Joseph (Joe) Gerber (1924-1996), after all, who envisioned and fundamentally shaped automation in this industry. Indeed, Joe Gerber is widely credited with leadership in the invention, development, and commercialization of factory automation systems that dramatically increased efficiency and product quality in at least a dozen industries, including drafting, plotting, CAD (computer aided design), cartography, commercial printing, and the fabrication of electronics, shoes, signs, engravings, billboards, and eyeglass lenses, as well as apparel and textiles.