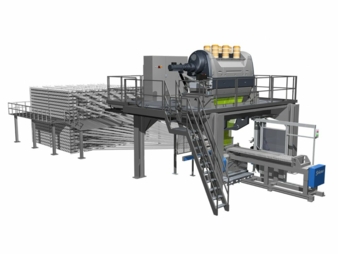

02.08.24 – Stäubli´s “TF30” weaving system

Revolutionizing technical fabric production

The “TF30” enables weaving mills to produce new types of technical fabrics in sectors ranging from medicine to transportation, aerospace, and more. Creating machinery to produce fabrics that are essential to global innovation is what motivates and inspires the teams at Stäubli.

Manufacturers value the flexibility and support needed to weave technical fabrics, especially with new materials and 3D forms.

A new era in technical fabrics

The “TF30” weaving system introduces several new features that distinguish it from conventional weaving technologies. With variable-height rapier weft insertion, it provides flexibility in shed programming and thus in weave structure. The weft-insertion concept ensures gentle yarn treatment, so the system can handle carbon and aramid yarns as well as ultra-sensitive ceramic yarns. Mills can choose from a wide range of jacquard machines and customized harnesses perfectly suited to their weaving applications.

Applications across sectors

With its portfolio of machines, Stäubli offers solutions for the production of printed circuit boards, airbags, lightweight carpets, and filters for the paper industry, ensuring precision, efficiency, and flexibility in the production of technical fabrics. Below are some examples of what weavers can achieve with the support of Stäubli solutions. The versatility of the “TF30” enables the production of a diverse array of technical fabrics. The “Safir S32” automation solution for drawing in is used by weaving mills around the world to produce PCB boards and glass applications. The “LXL Pro” jacquard machine provides all the necessary features for one-piece woven (OPW) applications, including top-quality airbags in any format. Featuring “Noemi” electronics architecture, this machine ensures a continuous jacquard weaving process at exceptional speed and energy efficiency. OPW weaving mills also use the “Tie Pro” warp-tying machine to achieve knots with short ends that are easily passed through the reed, ensuring the proper order. The Stäubli “Alpha 500 Lentec” weaving system provides ingenious features for uniform and precise loops, as required for lightweight carpets for the transportation sector. The heavy-duty dobbies for very large frame weaving machines are renowned for their robust construction and ability to withstand vibration encountered e. g. in the production of paper machine filters.

Partnering for progress

Stäubli´s commitment to innovation is reflected in its collaborative apporach, partnering with customers, universities, and industries. By leveraging decades of R&D experience, Stäubli continously enhances its range of solutions and services, ensuring that weaving mills can meet the evolving demands of the market. The flexibility of the “TF30” and other Stäubli systems allow these mills to adapt to new materials and 3D shapes, facilitating the creation of fabrics that were previously unattainable. This adability is crucial for industries that rely on advanced materials and complex fabric structures.

Visitors to Techtextil North America have the chance to learn more about this machine at the Stäubli booth in the German Pavilion in hall B.