23.03.22 – Sustainability

The next generation of materials from waste

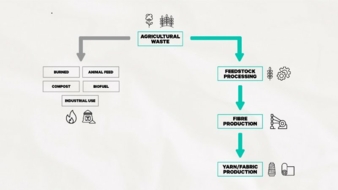

The latest project of Fashion for Good, a platform for sustainable fashion innovation, transforms agricultural waste into textile fibres.

Fashion for Good launched the ‘Untapped Agricultural Waste Project’ to validate and scale technologies that can successfully transform agricultural waste into sustainable textile fibres. The consortium project will assess the technical feasibility of natural fibres created by the selected innovators using agricultural waste such as rice husks, hemp, wheat straw, banana and pineapple.

A key area for decarbonisation

Agricultural waste poses significant challenges for farmers in South and Southeast Asia and in many cases the waste is not repurposed and is often burned. Up to 92 million tonnes of agricultural waste is burned annually* in India alone, which in 2017 resulted in approximately 149 million tonnes of CO2**.

At the same time, the extraction and processing of virgin, conventional fibres such as cotton and polyester accounts for up to 39% of greenhouse gas emissions in the textile supply chain – as highlighted in Fashion for Good’s recent report ‘Unlocking the Trillion-Dollar Fashion Decarbonisation Opportunity’. The report charts a funding and solution driven trajectory for the industry to meet its net-zero ambition. Raw Material innovation is essential to reducing these emissions, and the next generation of materials are key if the industry is to decarbonise its supply chain.

The potential of agricultural waste

The 18 month ‘Untapped Agricultural Waste Project’ brings together Fashion for Good partners Adidas, Bestseller, Vivobarefoot and supply chain partner Birla Cellulose as well as six innovators to explore innovations that can repurpose agricultural waste into viable new natural fibre blends. These fibre blends offer alternatives to conventional fibres and have the potential to displace virgin fibres derived from unsustainable materials such as oil. With the support of catalytic funding from Laudes Foundation, the project also leverages findings from their 2021 report, ‘Spinning Future Threads’ authored by the Institute for Sustainable Communities, the World Resources Institute India and Wageningen University and Research. The report maps agricultural waste in eight countries across South and Southeast Asia, identifying the untapped opportunities in agricultural waste streams including rice husks, wheat straw, banana and pineapple production, which are the focus of this project.

The six fibre innovators, AltMat, Bananatex, Chlorohemp, Agraloop by Circular Systems, HempTex India and 9Fiber, will be further developing a variety of different natural fibres and fibre blends with a focus on trialling the highest percentage of agricultural waste, while also achieving the necessary performance requirements. Birla Cellulose will work closely with the innovators providing expertise to develop and prepare their new materials for wider adoption in the fashion supply chain, with the participating project brand partners supporting the testing and eventual scaling of these fibres.

Katrin Ley, Managing Director, Fashion for Good:

“This ambitious project explores a new source of feedstocks for the fashion industry that, if scaled, will help drive both the agriculture and textile industry towards net-zero. We see great potential for these various agriculture waste streams that would otherwise have few secondary uses. By applying innovative technologies to develop natural fibres, we can diminish the pressure on existing natural fibres and shift away from unsustainable materials and sources.”

This first phase of the project concludes in December 2022. To further drive supply chain adoption and move beyond lab scale, the next phase of the project will pilot the agri-waste fibres from selected innovators in collaboration with partner brands and supply chain players in commercial facilities to produce larger quantities. This next phase ultimately aims to further enable brand offtake agreements and financing to facilitate scaling.