17.10.24 – Chemical solutions

The role of technical textiles in the automotive industry

Synergy of chemistry and textiles to improve performance.

Technical textiles play a crucial role in the automotive industry as high-performance fabric. This type of textile is used in airbags, safety belts, seat covers, insulation, floor coverings, floor carpets/mats, and filters. Up to 35 kilos of textiles are processed in a car. A considerable weight, but textiles can replace many other materials and thus reduce the total weight of a car. Depending on the exact end use, each type of textile must have specific properties. These properties are achieved using chemistry. In this way, the textile suddenly becomes a technical textile with specific properties: Flame retardant – oil, water and/or dirt repellent, antislip-effect, antistatic effect, wear-resistant. The integration of chemistry into the development of these textiles has led to significant advances and innovations, making cars lighter, safer, and more efficient.

Recyclable automotive floor carpet

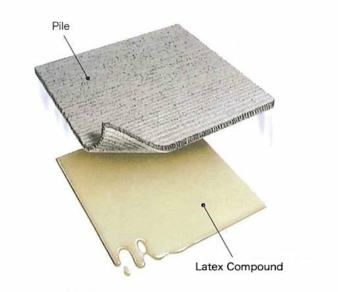

The EU has set itself the goal of being a leader in the field of sustainability. This is reflected in different or less use of materials, developments to extend the lifespan and high-quality processing of products after use (upcycling/circularity). A good example of a development that fits in with this vision is the recyclable back coating for automotive floor carpets from Schmits Chemical Solutions. This development enables the automotive industry to sustainably recycle the textiles they use. Floor carpets/mats in the automotive industry are constructed from different types of materials, mostly polyester yarns with a latex back coating. This back coating ensures anchoring of the pile and stability of the carpet. The disadvantage of the combination of polyester/latex is that it is not recyclable. Ultimately, carpets have to be burned or they end up in landfills.

Schmits has developed a solution, which makes the production of a mono carpet possible: a carpet made from one material. This makes carpets recyclable, because the SBR latex on carpets can be replaced by a new, recyclable back coating. Schmits recyclable solution for automotive polyester carpets is Bemicoat BCR PES. An additional advantage of the polyester back coating is weight reduction, because the same performance can be achieved with less material.

Other chemical solutions for the automotive industry are:

Bemicoat NPSD: PES-based recyclable anti-slip coating

Bemicoat BCR-PP: PP-based, good stability, low melting point

Bemiflame PES: flame retardant for polyester, Oeko-Tex Class I-IV

Bemifix PVL: polyvinyl alcohol (pva) solution used in natural, carbon-based alternatives

Bemiguard WR: fluorine free, foamable water, and dirt repellent

Technical textiles are essential for a modern automotive industry. The added value of chemistry cannot be underestimated. From improving safety and comfort to promoting sustainability and innovation, chemical finishes and coatings play a key role in shaping the future of the automotive industry. As the industry continues to evolve, the synergies between chemistry and textiles will undoubtedly continue to lead to breakthrough solutions that improve vehicle performance and efficiency.